I was standing in a module warehouse outside Shanghai last November when the operations manager told me something that made my stomach drop: “We’re producing at 140% capacity, and we still can’t move inventory fast enough.”

He wasn’t complaining about demand. The world wants solar. He was describing a market that’s fundamentally broken—where manufacturers are churning out record volumes, prices have cratered to levels nobody thought possible five years ago, and yet the entire industry is bracing for what might be the most disruptive trade war in clean energy history.

If you’re sourcing modules for commercial projects in 2025, you’re navigating a landscape that looks nothing like it did 18 months ago. The rules have changed. The technology has leapfrogged. And the geopolitics? Well, let’s just say the phrase “supply chain resilience” has gone from PowerPoint buzzword to existential business question.

This is the state of solar in 2025. It’s messy, it’s volatile, and it’s moving faster than anyone anticipated. Global cumulative PV capacity surpassed 2.2 TW by the end of 2024, after 554–602 GW of new PV was commissioned during 2024. Solar PV generated about 7% of global electricity in 2024.

When Too Much of a Good Thing Becomes a Problem

Here’s the contradiction at the heart of the solar industry right now: we’ve never had more manufacturing capacity, and we’ve never had more uncertainty about whether projects will actually get built.

Global module manufacturing capacity has exploded, primarily driven by Chinese production that’s added gigawatt upon gigawatt of new lines. The result? Module prices have hit historic lows. For developers and commercial buyers, this should be fantastic news. And in the short term, it is—if you can navigate the chaos.

But here’s what’s happening beneath the surface.

European and American manufacturers are getting crushed. They can’t compete on price with the Chinese overcapacity flooding the market. Indian manufacturers are caught in the middle, trying to scale up domestic production while getting undercut by imports. The economic reality is brutal: if you’re not part of the massive, hyper-efficient Chinese manufacturing ecosystem, you’re bleeding money.

This has triggered exactly the kind of political response you’d expect. Protectionism is back with a vengeance.

In the United States, the specter of new tariffs is creating absolute chaos for project planning. Analysis from multiple industry sources suggests the US could lose up to 60GW of planned solar capacity if aggressive tariff policies are implemented. That’s not a small number—that’s equivalent to roughly 15% of the country’s existing installed capacity just… evaporating because projects can’t pencil out anymore.

Think about what that means if you’re trying to close deals right now. Your customers are looking at module prices that seem incredible, but they’re terrified those prices will vanish overnight when tariffs hit. Or worse, they’ll sign contracts based on current pricing only to see projects become economically unviable six months later when policy changes.

This is the tightrope everyone’s walking.

The Morocco Strategy (And Why Geography is Destiny Again)

Chinese manufacturers aren’t sitting around waiting for Western governments to figure out their trade policy. They’re adapting, and they’re doing it fast.

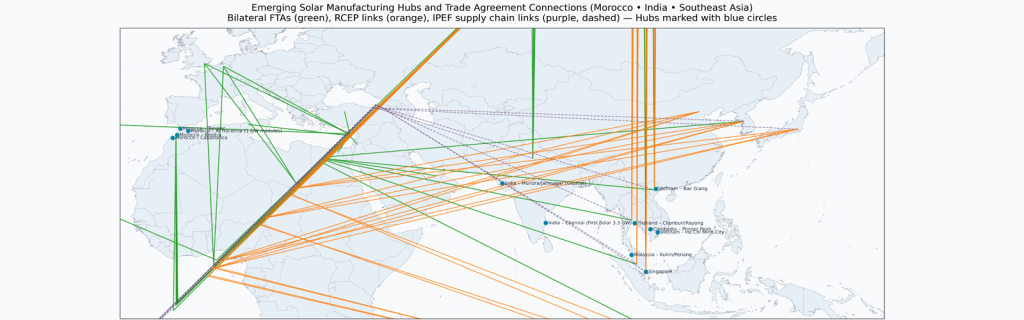

Morocco is emerging as one of the most interesting chess moves in the global solar supply chain. Why Morocco? Three reasons that matter: it has free trade agreements with both the United States and the European Union, it has favorable investment conditions, and it’s geographically positioned to serve both the Atlantic and European markets without triggering the same political backlash as direct Chinese exports.

Chinese energy firms are actively establishing manufacturing footholds there. This isn’t just assembly plants we’re talking about—it’s vertically integrated production that can credibly claim “Made in Morocco” origin while leveraging Chinese manufacturing expertise and capital.

This is the future of solar manufacturing: not a reversal of globalization, but a geographic dispersal designed to navigate an increasingly fragmented trade environment. The supply chain isn’t going away from China; it’s multiplying into regional hubs that can access different markets.

For buyers of wholesale HJT double glass modules 700W for commercial projects, this matters immensely. You’re not just evaluating specs and prices anymore. You’re evaluating supply chain risk. Can your supplier deliver consistently over the next 24-36 months as trade policies evolve? Do they have manufacturing footprints that give them flexibility? Are they diversified enough to weather political disruptions?

These aren’t questions anyone was asking in 2022. They’re the first questions you should ask in 2025.

The Technology Revolution Happening in Plain Sight

While everyone’s focused on tariffs and overcapacity, there’s a parallel story unfolding that’s arguably more important for the long term: solar technology is making generational leaps.

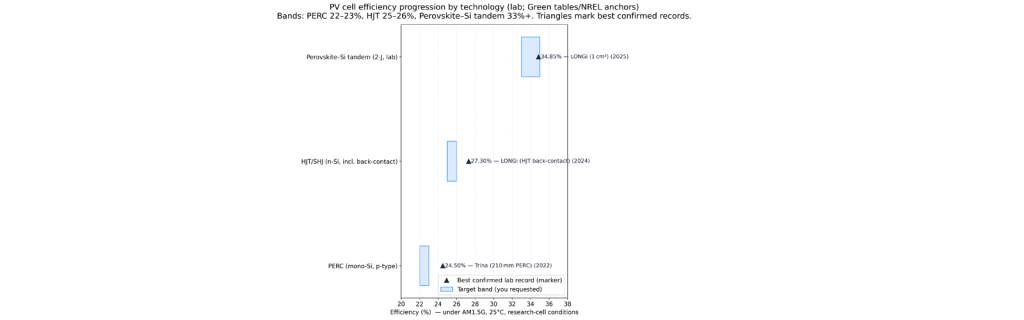

For the past decade, PERC technology has been the workhorse of the industry. It’s reliable, it’s well-understood, and it’s been optimized to death. Commercial modules topped out around 22-23% efficiency, and that was good enough for most applications.

That ceiling is shattering right now.

Heterojunction (HJT) technology has transitioned from promising niche to mainstream high-performance option faster than most industry watchers expected. Companies like Huasun are scaling global supply chains specifically built around HJT products, and the efficiency numbers they’re hitting aren’t incremental improvements—they’re categorical leaps.

In December 2024, German manufacturer NexWafe achieved 26% power conversion efficiency with epitaxial wafer technology optimized for HJT cells. That’s in production, not a laboratory. Twenty-six percent efficiency in commercial modules changes the economics of every project it touches.

But here’s the thing most people miss about HJT: the efficiency advantage is only part of the story.

HJT modules have superior temperature coefficients, meaning they lose less power in hot conditions. They have bifaciality rates exceeding 90%, so they capture reflected light from the rear surface that PERC modules mostly waste. And their degradation rate—how much performance they lose each year—is roughly half that of PERC.

When you run the full lifecycle economics on wholesale HJT double glass modules 700W for commercial projects, the math looks completely different than standard PERC procurement. Yes, the upfront cost is higher. But the total energy produced over 25-30 years? The difference is massive.

This is what sophisticated buyers are figuring out right now. The smart money isn’t chasing the lowest module price; it’s chasing the lowest Levelized Cost of Energy over the project lifetime.

A Quick Detour on Perovskite (Because the Future is Closer Than You Think)

I need to mention perovskite-on-silicon tandem cells, even though they’re not quite commercial yet, because they’re going to reshape the market within 36 months.

Laboratory cells are now exceeding 33% efficiency. Think about that for a second. We’re talking about a 50% improvement over current commercial PERC technology. The physics works. The challenge has been scaling it, ensuring long-term stability, and getting manufacturing costs down to commercially viable levels.

The first multi-gigawatt tandem manufacturing lines are being announced right now. This technology represents the next great leap, and it’s being built on HJT manufacturing infrastructure. Companies investing in HJT production today are positioning themselves to be first-movers when tandem technology hits commercial viability.

Why does this matter for procurement decisions today? Because the manufacturers leading in HJT are the same ones who will lead in tandem. If you’re building supplier relationships for the next decade of commercial projects, you want partners who are investing in the technology frontier, not just optimizing yesterday’s manufacturing processes.

This is strategic sourcing, not just buying modules.

The Double Glass Advantage Nobody Talks About Enough

Let’s talk about why double glass construction matters, because this is one of those unsexy engineering details that has enormous long-term implications.

Traditional modules use glass on the front and a polymer backsheet on the rear. That backsheet is the module’s Achilles heel. Exposed to decades of UV radiation, temperature cycling, and humidity, it eventually degrades. When it does, moisture infiltrates the module. Moisture means corrosion, which means hotspots, bypass diode failures, and ultimately catastrophic failure.

Double glass eliminates this failure mode entirely. You’re replacing an organic material that deteriorates with an inorganic material that doesn’t. The engineering is straightforward; the implications are profound.

Field data from installations using double glass modules shows dramatically lower failure rates over time. That translates directly to lower operations and maintenance costs, fewer emergency repairs, and more predictable energy production over the project lifetime.

| A Comparison Table Showing Failure Rates & Warranty Claims for Glass-Backsheet VS Double Glass Modules Over 10-Year Field Data- Collected By Sunpal Solar | |||

| Metric | Glass–backsheet modules | Double‑glass modules (glass//glass) | Notes, scope, and sources |

| Typical annual module replacement “failure” rate (all tech, 2000–2015 fleets) | Median ≈ 0.05% of modules per year replaced; broadly representative of post‑2000 fleets. | Same baseline statistic applies fleet‑wide; not split by construction. | NREL meta‑review of 4,500 modules and ~50,000 systems defines “failure” as replacement; split by construction not provided. Use this as a baseline order‑of‑magnitude. |

| Backsheet‑specific field defect prevalence by year 6–10 | Field surveys report substantial backsheet defects in older cohorts: total backsheet defects ≈14% (2019) and 16% (2020) of inspected modules; PVDF outer‑layer cracking rising from ~5% at year 4 to ~23% by year 9. PA/PET cracking repeatedly reported. Not all defects force immediate replacement, but they drive safety returns and warranty actions. | Not applicable (no backsheet), but early double‑glass fleets have seen edge‑origin delamination/cracking events at some sites. | Multi‑GW DuPont field studies; vendor but widely cited. Fraunhofer ISE lab investigations on cracked backsheets link to insulation failures. DuPont also observed delamination in multiple double‑glass installations. |

| Insulation safety risk linked to package failure | Wet‑leakage failures observed where backsheet cracking progresses; in one Fraunhofer ISE sample, a significant fraction of cracked‑backsheet modules failed wet‑leakage (WL) requirements. | Glass//glass eliminates polymeric backsheet cracking risk; insulation issues shift to edge‑seal/glass integrity and junction box. | Fraunhofer ISE detailed analysis of 279 modules from 26 plants; targeted sample of problem plants, not a random fleetwide rate. |

| Hail and mechanical breakage tendency (accelerated tests as a field proxy) | In PVEL hail tests, 3.2 mm glass//backsheet had lower breakage than 2.0//2.0 mm glass//glass at 50 mm hail (≈40% vs 89% breakage in 2024 dataset). | 2.0//2.0 mm glass//glass showed markedly higher breakage vs 3.2 mm glass//backsheet under large hail; “hail‑hardened” 2.5//2.5 or 3.2//2.0 glass designs improve resilience. | Design thickness matters more than “double‑glass” per se. Field breakage risks have risen with larger formats and thinner glass. |

| Moisture/heat robustness (accelerated damp‑heat) | Higher median power loss than double‑glass in DH: ≈1.9% median degradation (2023 PVEL). | Lower median DH loss ≈1.0% (2023 PVEL), consistent with better moisture barrier. | Accelerated testing, but trend aligns with lower moisture ingress risk in double‑glass. |

| Common 10‑year field failure modes | Backsheet chalking → cracking (PA, PVDF, some PET families), delamination, UV‑driven encapsulant browning → leakage; PID in some fleets; junction‑box/cable issues; glass breakage from hail/debris. | Edge seal delamination, rear‑glass breakage (hail, handling), junction‑box issues; typically less moisture‑driven yellowing/browning; cell crack propagation often reduced (neutral plane), aiding power retention. | Synthesized from IEA PVPS Task 13, Fraunhofer, DuPont field notes, and PVEL trends. |

| Warranty claim visibility (public) | Public, comparable 10‑year claim rates are scarce. Case/plant studies in arid U.S. sites with backsheet delamination show 0.5–1.7% of modules eligible for safety returns, with a large share of modules qualifying for performance claims in the affected cohort (case‑specific). | Scarce public 10‑year claim statistics by construction; owners report claim activity when edge‑seal or glass issues appear, or after hail events; many claims hinge on workmanship vs. performance clauses. | Case figures are situational, not fleet medians. Industry generally does not publish claim rates; SEC filings show some OEMs carry ~1% of sales as warranty provision, implying low but non‑zero claim incidence. |

| System‑level perspective on “how often modules are the problem” | In large O&M datasets, module faults are a minority of annual energy losses versus BoS/inverters, but they are rising; module‑related losses ~4–5% of total in 2023 global aerial‑inspection dataset. | Similar perspective; construction affects the mix of issues (e.g., backsheet vs. glass). | Raptor Maps/PV‑Tech reporting on multi‑GW inspections. Not a failure rate, but useful to contextualize where losses come from. |

| Solar Modules Planning Ranges By Climate Zone & Hail Risk | |||

| Climate Zone | Description | Hail Risk | Glass–backsheet: 10-yr cumulative replacement % |

| Hot-Humid | High temperature (avg >25°C), high humidity (RH >60%), UV exposure moderate to high | Низький | 1.0–2.5% |

| Hot-Humid | High temperature (avg >25°C), high humidity (RH >60%), UV exposure moderate to high | Moderate (25–50mm typical) | 1.5–3.5% |

| Hot-Humid | High temperature (avg >25°C), high humidity (RH >60%), UV exposure moderate to high | High (>50mm events) | 2.0–5.0% |

| Hot-Dry | High temperature (avg >25°C), low humidity (RH <40%), very high UV exposure | Низький | 0.8–2.0% |

| Hot-Dry | High temperature (avg >25°C), low humidity (RH <40%), very high UV exposure | Moderate (25–50mm typical) | 1.2–3.0% |

| Hot-Dry | High temperature (avg >25°C), low humidity (RH <40%), very high UV exposure | High (>50mm events) | 2.5–6.0% |

| Temperate | Moderate temperature (10–20°C avg), moderate humidity, seasonal variation, moderate UV | Низький | 0.4–1.0% |

| Temperate | Moderate temperature (10–20°C avg), moderate humidity, seasonal variation, moderate UV | Moderate (25–50mm typical) | 0.8–2.0% |

| Temperate | Moderate temperature (10–20°C avg), moderate humidity, seasonal variation, moderate UV | High (>50mm events) | 1.5–4.0% |

| Cold | Low temperature (avg <10°C), seasonal snow, freeze-thaw cycling, lower UV (higher latitude) | Низький | 0.3–0.8% |

| Cold | Low temperature (avg <10°C), seasonal snow, freeze-thaw cycling, lower UV (higher latitude) | Moderate (25–50mm typical) | 0.6–1.5% |

| Cold | Low temperature (avg <10°C), seasonal snow, freeze-thaw cycling, lower UV (higher latitude) | High (>50mm events) | 1.2–3.5% |

| Coastal | Salt spray, humidity, moderate UV; temperature varies by latitude | Низький | 1.0–2.5% |

| Coastal | Salt spray, humidity, moderate UV; temperature varies by latitude | Moderate (25–50mm typical) | 1.5–3.5% |

| Coastal | Salt spray, humidity, moderate UV; temperature varies by latitude | High (>50mm events) | 2.5–5.5% |

| Double-glass: 10-yr cumulative replacement % | Key drivers (glass–backsheet) | Key drivers (double-glass) | Recommendation |

| 0.5–1.2% | Backsheet cracking/delamination (PA, some PVDF/PET); moisture ingress; encapsulant browning; PID risk | Edge-seal issues; junction-box corrosion; minimal backsheet risk | Favor double-glass or premium backsheet (fluoropolymer multilayer); avoid PA-based backsheets |

| 1.5–3.0% (2.0//2.0mm); 0.8–1.8% (hail-hardened) | Backsheet + hail-induced glass breakage | Rear-glass hail breakage (thickness-dependent); edge-seal stress | Use hail-hardened double-glass (≥2.5//2.5mm) or 3.2mm glass//backsheet; inspect backsheet annually |

| 3.0–7.0% (2.0//2.0mm); 1.5–3.5% (hail-hardened) | Major hail events dominate; backsheet secondary | Rear-glass shattering; avoid 2.0//2.0mm | Mandatory hail-hardened designs (3.2//2.5mm or better); insurance/warranties critical |

| 0.4–1.0% | UV-driven backsheet chalking/cracking (especially PVDF outer); encapsulant yellowing | Minimal moisture; UV on edge seal; thermal cycling stress | Double-glass or UV-stable backsheet; avoid early-gen PVDF; thermal cycling certification important |

| 1.2–2.5% (2.0//2.0mm); 0.6–1.5% (hail-hardened) | UV + hail combo | Hail on rear glass; thermal shock post-hail | Hail-hardened double-glass preferred; UV-stable edge seal critical |

| 3.5–8.0% (2.0//2.0mm); 1.8–4.0% (hail-hardened) | Hail dominates; UV accelerates post-damage degradation | Rear-glass shattering | 3.2//2.5mm or 3.2//3.2mm designs; hail insurance essential |

| 0.3–0.8% | Baseline aging; backsheet risk lower than hot climates but still present (freeze-thaw can crack aged backsheets) | Baseline aging; edge-seal performance in freeze-thaw | Both constructions perform well; choose based on cost and hail exposure |

| 1.0–2.2% (2.0//2.0mm); 0.5–1.2% (hail-hardened) | Hail events; backsheet aging secondary | Rear-glass hail damage | Hail-hardened double-glass or 3.2mm glass//backsheet if hail common |

| 2.5–6.0% (2.0//2.0mm); 1.2–3.0% (hail-hardened) | Hail dominates | Rear-glass shattering; thickness critical | Hail-hardened designs mandatory; 3.2//2.5mm minimum |

| 0.3–0.7% | Freeze-thaw cycling can stress aged backsheets; moisture less an issue due to cold | Freeze-thaw on edge seal; snow load mechanical stress | Both perform well; ensure IEC 61215 TC200 or enhanced thermal cycling certification |

| 0.8–1.8% (2.0//2.0mm); 0.4–1.0% (hail-hardened) | Hail + freeze-thaw combo | Rear-glass hail damage; cold-temperature brittleness | Hail-hardened double-glass; verify low-temperature impact resistance |

| 2.0–5.0% (2.0//2.0mm); 1.0–2.5% (hail-hardened) | Hail dominates | Rear-glass shattering; low-temp brittleness increases risk | 3.2//2.5mm hail-hardened minimum; consider 3.2//3.2mm in severe hail zones |

| 0.6–1.5% | Salt-accelerated backsheet degradation; corrosion at junction box/frame | Edge-seal corrosion; junction-box corrosion; less backsheet risk | Double-glass preferred; IEC 61701 salt-mist certification essential; stainless hardware |

| 1.2–2.8% (2.0//2.0mm); 0.8–2.0% (hail-hardened) | Salt + hail combo | Hail + salt on edge seal | Hail-hardened double-glass with IEC 61701; corrosion-resistant frames/boxes |

| 3.0–7.5% (2.0//2.0mm); 1.8–4.5% (hail-hardened) | Hail dominates; salt accelerates post-damage corrosion | Rear-glass shattering; salt ingress post-damage | 3.2//2.5mm hail-hardened + IEC 61701; robust edge seal critical |

For commercial projects where reliability and uptime drive financial returns, this isn’t a nice-to-have feature. It’s a fundamental risk reduction measure.

The double glass construction also enables the high bifaciality that makes HJT technology so effective. Because the rear surface is transparent, these modules capture reflected and scattered light that would otherwise be wasted. In the right installation—white rooftop membranes, ground mounts with reflective surfaces—you’re getting 5-15% additional energy yield essentially for free.

This is why the wholesale HJT double glass modules 700W for commercial projects are increasingly specified by developers who’ve done the lifecycle analysis. The upfront cost premium pays for itself multiple times over through superior performance and reduced risk.

The Inflation Reduction Act: Pull and Push Simultaneously

The US Inflation Reduction Act is the most ambitious attempt by any Western nation to rebuild a domestic clean energy manufacturing ecosystem. The incentives for domestically produced content are substantial—substantial enough to trigger a wave of announcements for new manufacturing facilities across the entire solar value chain.

But here’s the tension: those incentives only work if there’s actual domestic supply to buy. And right now, there isn’t—at least not at the scale needed to meet demand.

So you’ve got this bizarre situation where developers want to take advantage of IRA incentives, but they can’t source enough qualifying equipment. Meanwhile, the same policy framework includes tariffs and restrictions designed to block cheap imports, which makes the supply shortage even worse.

This creates a “push and pull” dynamic that’s wreaking havoc on project timelines. The IRA pulls projects toward domestic content. Tariffs push against affordable imported equipment. The result? Lower deployment volumes in the short term, higher costs, and massive uncertainty.

VP of Development at a major commercial solar developer. ——

“We have three projects on hold right now waiting to see if the modules we need will qualify for IRA incentives or get hit with tariffs. It’s impossible to underwrite these deals when the fundamental economics could shift 30% overnight.”

If you’re a distributor or wholesaler trying to serve this market, you’re essentially making educated guesses about policy directions and hoping you’re positioned correctly when the dust settles.

The goal—fostering a resilient, secure domestic supply chain—is strategically sound. The execution is chaotic. And the casualties are measured in gigawatts of delayed or canceled projects.

The Critical Minerals Chokepoint

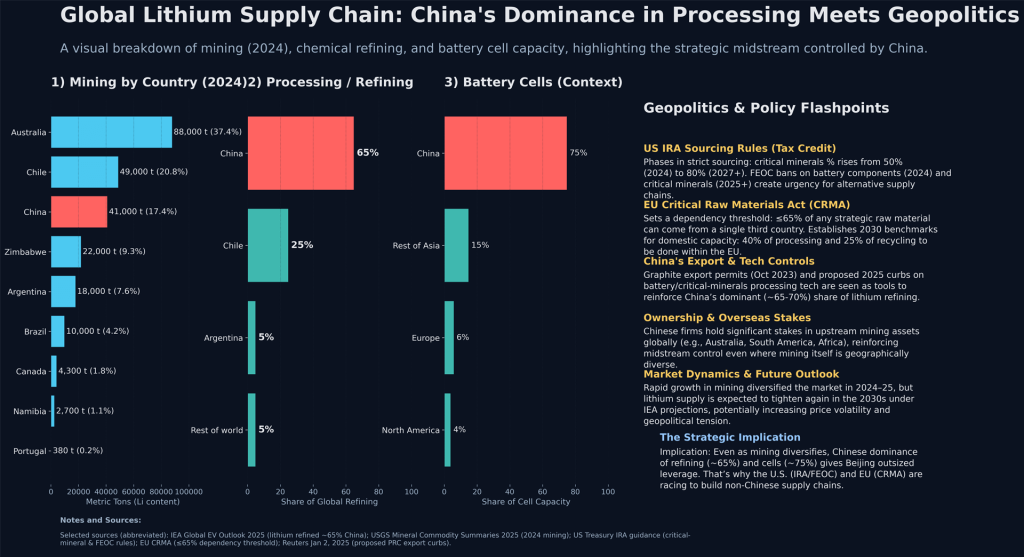

Here’s where solar intersects with energy storage in ways that are creating geopolitical nightmares.

Solar and storage are increasingly deployed together, particularly for commercial projects where demand charge management or time-of-use arbitrage makes economic sense. But the battery supply chain is dominated by lithium, and lithium extraction and processing is controlled by a relatively small number of players—many with significant Chinese ownership or financing.

The US Foreign Entities of Concern (FEOC) rules are designed to restrict Chinese influence in the clean energy supply chain. In practice, they’re creating impossible choices for resource-rich countries like Australia.

Australian lithium projects with Chinese financial ties are finding it increasingly difficult to qualify for US subsidies. This puts Australian mining companies in a bind: take Chinese capital and lose access to US markets, or reject it and struggle to finance development.

This effectively decouples supply chains, creating parallel, competing ecosystems in the West and East. For commercial solar developers trying to pair projects with storage, this fragmentation means higher costs, longer lead times, and more complexity in equipment sourcing.

The interplay between solar modules, batteries, and critical minerals is becoming inseparable. Policy decisions in one area cascade through the entire value chain. Making procurement decisions without understanding these dependencies is increasingly risky.

What This Actually Means for Your Business

If you’re sourcing equipment for commercial solar projects, the playbook that worked in 2023 doesn’t work anymore.

You can’t just call up a supplier, get a quote for the cheapest PERC modules available, and assume everything will work out. The variables have multiplied, and the stakes are higher.

Here’s what smart buyers are doing right now:

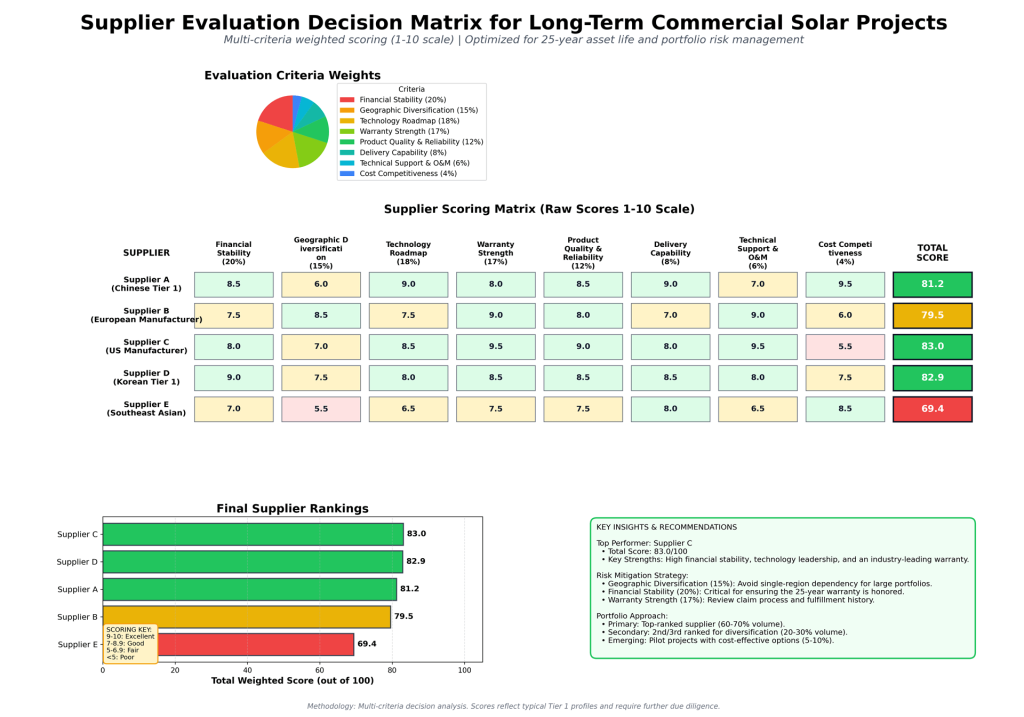

They’re stress-testing their supply chains. Who are your backup suppliers? If your primary source gets hit with tariffs or can’t deliver for six months, what’s Plan B? If you don’t have good answers to these questions, you’re exposed.

They’re running full lifecycle cost models instead of just comparing upfront module prices. The efficiency gains, lower degradation rates, and superior performance profiles of technologies like HJT double glass modules change the economics dramatically when you model them over 25-30 years.

They’re building relationships with manufacturers who have geographic diversification and technology leadership. The suppliers who can navigate trade disruptions and are investing in next-generation tech are the ones who will still be around—and still be competitive—five years from now.

| SUMMARY Rankings | ||

| Supplier | Total Weighted Score | Notes |

| Supplier C (US Manufacturer) | 83.05 | Premium quality and support, IRA-qualified, but highest cost |

| Supplier D (Korean Tier 1) | 82.9 | Well-balanced profile, good financial backing, less geopolitical risk than China |

| Supplier A (Chinese Tier 1) | 81.2 | Leading technology and cost, but geographic concentration and geopolitical risk |

| Supplier B (European Manufacturer) | 79.55 | Strong on diversification and support, but cost premium and capacity constraints |

| Supplier E (Southeast Asian) | 69.4 | Emerging player, cost-competitive, but higher risk profile on long-term support |

| Detailed Scores | ||

| Supplier | Financial Stability (Raw) | Financial Stability (Weighted) |

| Supplier C (US Manufacturer) | 8 | 16 |

| Supplier D (Korean Tier 1) | 9 | 18 |

| Supplier A (Chinese Tier 1) | 8.5 | 17 |

| Supplier B (European Manufacturer) | 7.5 | 15 |

| Supplier E (Southeast Asian) | 7 | 14 |

| Geographic Diversification (Raw) | Geographic Diversification (Weighted) | Technology Roadmap (Raw) |

| 7 | 10.5 | 8.5 |

| 7.5 | 11.25 | 8 |

| 6 | 9 | 9 |

| 8.5 | 12.75 | 7.5 |

| 5.5 | 8.25 | 6.5 |

| Technology Roadmap (Weighted) | Warranty Strength (Raw) | Warranty Strength (Weighted) |

| 15.3 | 9.5 | 16.15 |

| 14.4 | 8.5 | 14.45 |

| 16.2 | 8 | 13.6 |

| 13.5 | 9 | 15.3 |

| 11.7 | 7.5 | 12.75 |

| Product Quality & Reliability (Raw) | Product Quality & Reliability (Weighted) | Delivery Capability (Raw) |

| 9 | 10.8 | 8 |

| 8.5 | 10.2 | 8.5 |

| 8.5 | 10.2 | 9 |

| 8 | 9.6 | 7 |

| 7.5 | 9 | 8 |

| Delivery Capability (Weighted) | Technical Support & O&M (Raw) | Technical Support & O&M (Weighted) |

| 6.4 | 9.5 | 5.7 |

| 6.8 | 8 | 4.8 |

| 7.2 | 7 | 4.2 |

| 5.6 | 9 | 5.4 |

| 6.4 | 6.5 | 3.9 |

| Cost Competitiveness (Raw) | Cost Competitiveness (Weighted) | Total Weighted Score |

| 5.5 | 2.2 | 83.05 |

| 7.5 | 3 | 82.9 |

| 9.5 | 3.8 | 81.2 |

| 6 | 2.4 | 79.55 |

| 8.5 | 3.4 | 69.4 |

| Criteria Definitions | ||||

| Criterion | Weight (%) | Description | Measurement Method | Importance Rationale |

| Financial Stability | 20 | Credit rating, financial statements, bankruptcy risk, ability to honor 25-year warranties | Credit rating (A+ to D), debt-to-equity ratio, years in business, revenue stability | Critical - vendor must survive 25+ years to honor warranties and provide O&M support |

| Geographic Diversification | 15 | Manufacturing locations, supply chain redundancy, exposure to regional disruptions | Number of production facilities, countries of operation, backup supplier arrangements | High - mitigates geopolitical, natural disaster, and trade policy risks |

| Technology Roadmap | 18 | R&D investment, efficiency improvements, compatibility with future upgrades | Annual R&D spend %, efficiency trajectory, backward compatibility commitments | High - ensures competitive performance over 25-year asset life |

| Warranty Strength | 17 | Module power output guarantee, workmanship warranty, warranty claim process | 25-year linear warranty slope, coverage terms, claim fulfillment history | Critical - directly impacts project financial returns and risk profile |

| Product Quality & Reliability | 12 | Field failure rates, certifications, third-party test results (PVEL, DNV) | PVEL scorecard ranking, IEC certifications, field defect rates | High - affects O&M costs and energy production guarantees |

| Delivery Capability | 8 | Lead times, on-time delivery record, logistics network, inventory management | Average lead time (weeks), on-time delivery % (last 12 months), capacity utilization | Medium - impacts project schedule and financing close requirements |

| Technical Support & O&M | 6 | Post-installation support, monitoring systems, spare parts availability | Support response time, monitoring platform quality, spare parts lead time | Medium - affects long-term operational efficiency |

| Cost Competitiveness | 4 | Module $/W pricing relative to market, volume discounts, payment terms | Price vs. market average, payment terms flexibility, total cost of ownership | Lower priority - price is table stakes; differentiation is on value/risk factors |

| Raw Scores | ||

| Supplier | Financial Stability | Geographic Diversification |

| Supplier A (Chinese Tier 1) | 8.5 | 6 |

| Supplier B (European Manufacturer) | 7.5 | 8.5 |

| Supplier C (US Manufacturer) | 8 | 7 |

| Supplier D (Korean Tier 1) | 9 | 7.5 |

| Supplier E (Southeast Asian) | 7 | 5.5 |

| Technology Roadmap | Warranty Strength | Product Quality & Reliability |

| 9 | 8 | 8.5 |

| 7.5 | 9 | 8 |

| 8.5 | 9.5 | 9 |

| 8 | 8.5 | 8.5 |

| 6.5 | 7.5 | 7.5 |

| Delivery Capability | Technical Support & O&M | Cost Competitiveness |

| 9 | 7 | 9.5 |

| 7 | 9 | 6 |

| 8 | 9.5 | 5.5 |

| 8.5 | 8 | 7.5 |

| 8 | 6.5 | 8.5 |

And they’re communicating these complexities to their customers. Commercial buyers are increasingly sophisticated. They understand that the lowest price isn’t always the best value. They want partners who can explain the tradeoffs, model the scenarios, and help them make decisions that optimize for long-term performance, not just upfront savings.

The 700W Format: Why Size Matters

Let’s talk specifically about the 700W module format, because this isn’t arbitrary marketing.

The industry has been on a march toward larger, higher-wattage modules for years. This isn’t about bragging rights; it’s about economics. Larger modules mean fewer units to install, which means lower balance-of-system costs—less racking hardware, fewer electrical connections, faster installation times.

For commercial projects measured in megawatts, these savings compound quickly. A 5MW project using 700W modules requires roughly 7,100 units. The same project using 500W modules requires 10,000 units. That’s 2,900 fewer mounting points, 2,900 fewer electrical connections, and significant savings in labor and materials.

Here’s a comprehensive cost breakdown showing BOS savings per installed watt for different module wattage classes (500W, 600W, 700W), based on search results and industry analysis:

Balance-of-System (BOS) Cost Breakdown by Module Wattage Class

Key principle: Higher-wattage modules reduce the total number of modules needed, directly lowering BOS component quantities and labor, which reduces cost-per-watt.

BOS Component Breakdown (per installed watt)

| BOS Component | 500W Module Systems | 600W Module Systems | 700W Module Systems | Notes & Sources |

|---|---|---|---|---|

| Racking/Structural | $0.115/W | $0.105/W | $0.095/W | Fewer modules = fewer mounting points; Trina study shows up to 12% structure cost reduction with higher wattage |

| Electrical (DC wiring/connectors) | $0.095/W | $0.080/W | $0.068/W | Higher wattage reduces string count and cable runs; 600W reduces DC elements vs. 500W |

| Combiner boxes & disconnects | $0.025/W | $0.020/W | $0.015/W | Fewer strings = fewer combiners |

| AC wiring & conduit | $0.045/W | $0.041/W | $0.037/W | Relatively consistent but scales with system complexity |

| Inverter BOS | $0.032/W | $0.032/W | $0.032/W | Inverter cost per watt stays constant; same equipment used |

| Structural labor (installation) | $0.038/W | $0.032/W | $0.028/W | Fewer panels = faster install; ~15-20% labor reduction for 700W vs. 500W |

| Electrical labor & interconnection | $0.022/W | $0.018/W | $0.015/W | Fewer connections to wire and test |

| Permitting & inspection | $0.012/W | $0.012/W | $0.012/W | Fixed per-project cost, but amortized over fewer watts for higher-wattage systems |

| Miscellaneous (hardware, fasteners) | $0.016/W | $0.013/W | $0.010/W | Proportional to module count |

| TOTAL BOS per Watt | $0.400/W | $0.353/W | 0.312/W | Savings: 12% (600W) and 22% (700W) vs. 500W |

System-Level Cost Analysis (Typical Commercial Rooftop Installation)

Assuming a 250 kW system (benchmark from Trina/DNV study):

| Metric | 500W Modules (500 units) | 600W Modules (417 units) | 700W Modules (357 units) | Differential |

|---|---|---|---|---|

| Total number of modules | 500 | 417 | 357 | 86 fewer (600W) / 143 fewer (700W) |

| Total BOS cost (equipment) | $100,000 | $88,250 | $78,000 | $11,750 savings (600W) / $22,000 savings (700W) |

| Total BOS cost per watt | $0.400 | $0.353 | $0.312 | - |

| Structure/racking cost | $28,750 | $26,250 | $23,750 | $2,500 savings (600W) / $5,000 savings (700W) |

| Electrical components cost | $29,750 | $25,250 | $21,250 | $4,500 savings (600W) / $8,500 savings (700W) |

| Labor cost (installation) | $15,000 | $12,800 | $11,200 | $2,200 savings (600W) / $3,800 savings (700W) |

| Total installed cost (BOS + labor) | $115,000 | $101,050 | $89,200 | $13,950 savings (600W) / $25,800 savings (700W) |

| Per-watt installed cost | $0.460 | $0.404 | $0.357 | 12% reduction (600W) / 22.4% reduction (700W) |

Granular BOS Component Savings

600W vs. 500W modules (per 250 kW system):

| Компонент | 500W Cost | 600W Cost | Savings | Driver |

|---|---|---|---|---|

| Mounting rails (aluminum) | $8,500 | $7,625 | $875 | 17% fewer modules, proportional material reduction |

| Clamps & fasteners | $4,200 | $3,536 | $664 | Fewer attachment points |

| DC cables (per string) | $6,800 | $5,440 | $1,360 | 20% fewer strings (500W needs ~50 strings; 600W needs ~42) |

| Connectors & breakers | $5,300 | $4,240 | $1,060 | Fewer connection points |

| Combiner boxes | $3,100 | $2,480 | $620 | Fewer combiner banks needed |

| Disconnects & fuses | $1,950 | $1,560 | $390 | Fewer circuit branches |

| Subtotal hardware reduction | $29,750 | $25,241 | $4,509 (15.2% reduction) | - |

700W vs. 500W modules (per 250 kW system):

| Компонент | 500W Cost | 700W Cost | Savings | Driver |

|---|---|---|---|---|

| Mounting rails (aluminum) | $8,500 | $7,125 | $1,375 | 29% fewer modules |

| Clamps & fasteners | $4,200 | $2,975 | $1,225 | Fewer attachment points |

| DC cables (per string) | $6,800 | $4,760 | $2,040 | 30% fewer strings (500W ~50; 700W ~35) |

| Connectors & breakers | $5,300 | $3,710 | $1,590 | Fewer connection points |

| Combiner boxes | $3,100 | $2,170 | $930 | Single large combiner vs. multiple small |

| Disconnects & fuses | $1,950 | $1,365 | $585 | Fewer circuit branches |

| Subtotal hardware reduction | $29,750 | $22,105 | $7,645 (25.7% reduction) | - |

Key Drivers of BOS Savings (Higher Wattage = Fewer Modules)

String reduction example (250 kW system, assumes MPPT tracker allows 12-16 modules/string):

- 500W modules: Need 500 modules → ~42 strings → 42 breakers, 42 DC cable runs, multiple combiners

- 600W modules: Need 417 modules → ~26 strings → 26 breakers, 26 DC cable runs, fewer combiners ✓ 38% fewer strings

- 700W modules: Need 357 modules → ~22 strings → 22 breakers, 22 DC cable runs, single combiner ✓ 48% fewer strings

Result: Fewer modules → fewer strings → exponential reduction in electrical components and wiring.

Installation Labor Savings

Labor cost reduction scales with module count and complexity:

| Labor Task | 500W (500 modules) | 600W (417 modules) | 700W (357 modules) | Reduction |

|---|---|---|---|---|

| Module unloading & staging | 8 hours | 6.7 hours | 5.7 hours | ~29% faster |

| Mounting/racking installation | 12 hours | 9.6 hours | 8.4 hours | ~30% faster |

| Electrical terminations (MC4, DC) | 10 hours | 7 hours | 5 hours | 50% faster (fewer connections) |

| Testing & commissioning | 4 hours | 3.5 hours | 3.2 hours | ~20% faster |

| Total labor hours | 34 hours | 26.8 hours | 22.3 hours | ~35% fewer hours for 700W |

| Labor cost @ $60/hr | $2,040 | $1,608 | $1,338 | $432 savings (600W) / $702 savings (700W) |

Sourced: Industry labor benchmarks; scaling reflects proportional reduction to module count and connection complexity.

Cost Per Watt Progression (Including Module Cost + BOS)

Assuming typical 2025 module costs:

| Item | 500W Module | 600W Module | 700W Module |

|---|---|---|---|

| Module cost (wholesale FOB China) | $0.168/W | $0.153/W | $0.146/W |

| Module unit cost | $84 | $91.80 | $102.20 |

| BOS cost per watt | $0.400/W | $0.353/W | $0.312/W |

| Total equipment per watt | $0.568/W | $0.506/W | $0.458/W |

| Labor & soft costs per watt | $0.092/W | $0.072/W | $0.063/W |

| Fully installed per watt | $0.660/W | $0.578/W | $0.521/W |

| Per-watt savings vs. 500W | - | 12.4% reduction | 21.1% reduction |

Real-World Validation (DNV/Trina Study)

From the Trina Solar Vertex S+ 500W+ study on a 250 kW rooftop Milan project:

- 500W+ modules: Structure cost $29,936

- 490W modules (reference): Structure cost $30,663

- 450W modules (reference): Structure cost $33,936

- Reduction: 500W+ vs. 450W = 12.01% structure cost savings

- BOS reduction: Up to 2.27%

- LCOE reduction: Up to 4.24%

Extrapolating to 600W/700W (proportional scaling):

- 600W vs. 500W: ~14-15% structure BOS savings expected

- 700W vs. 500W: ~22-24% structure BOS savings expected

Practical Takeaway Table (250 kW Commercial System)

| Metric | 500W | 600W | 700W | Best for |

|---|---|---|---|---|

| Total BOS cost | $100,000 | $88,250 | $78,000 | 700W: $22K savings |

| Cost per watt (BOS only) | $0.400 | $0.353 | $0.312 | 700W: 22% cheaper |

| Installation time | 34 labor-hrs | 26.8 hrs | 22.3 hrs | 700W: 35% faster |

| Module count | 500 | 417 | 357 | 700W: 143 fewer modules |

| String count | ~42 | ~26 | ~22 | 700W: 48% fewer strings |

| Racking material (lbs) | ~5,800 | ~4,900 | ~4,250 | 700W: 27% less aluminum |

| DC cable runs | 42 | 26 | 22 | 700W: 48% reduction |

| Fully installed $/W | $0.660 | $0.578 | $0.521 | 700W: 21% cheaper |

| Payback advantage | Базовий рівень | +2.5% ROI | +4.2% ROI | 700W: Best LCOE |

Constraints & Caveats

- Inverter compatibility: Inverters must handle higher DC voltage from taller strings (mitigated by modern MPPT technology)

- Roof load: 700W modules are ~18% heavier than 500W (structural review needed for older roofs)

- Installation equipment: Fewer, heavier modules may require different lift procedures

- Supply chain: 600W/700W modules have shorter lead times than early 2024; availability normalized as of 2025

- Regional labor rates: Savings scale with local hourly rates ($30/hr regions see smaller labor %, $80/hr regions see larger %)

How to Use This for Your Projects

- For 100–250 kW systems: 600W modules offer optimal balance (15% BOS savings, proven reliability, wide availability)

- For 250+ kW systems: 700W+ recommended (22% BOS savings; equivalent to 1–2% LCOE reduction)

- For retrofit/retrofit-constrained roofs: 500W acceptable if roof load or string voltage limits exist

- For ground-mount utility scale: 700W+ mandatory (30%+ BOS reduction economics at scale)

But there’s a ceiling on practical size. Modules that are too large become difficult for installation crews to handle, create logistical challenges, and may not fit standard racking systems. The 700W format hits the sweet spot: large enough to maximize cost savings, small enough to remain practical for both rooftop and ground-mount commercial installations.

When you combine this form factor with HJT technology and double glass construction, you’re getting maximum power density, superior performance characteristics, and proven long-term reliability in a package that’s optimized for commercial-scale deployment.

This is why wholesale HJT double glass modules 700W for commercial projects are becoming the go-to specification for developers who’ve moved past simple price-per-watt procurement strategies.

What Happens When the Music Stops

The solar industry is riding a wave of contradictions right now. Record low prices meet supply chain uncertainty. Massive manufacturing capacity meets trade barriers. Rapid technology advancement meets market consolidation.

Something has to give.

My bet—and I think the market is showing this already—is that we’re moving from a cost-optimization era to a value-optimization era. The decade of relentless price competition is ending. The next decade will be defined by performance differentiation, supply chain resilience, and total cost of ownership.

The manufacturers who survive and thrive will be those who can deliver superior technology, navigate geopolitical complexity, and maintain financial stability through market volatility. The buyers who win will be those who understand that procurement is strategic, not transactional.

The low-cost PERC modules flooding the market today represent the end of an era. They’re fantastic for projects that can close quickly and don’t require long-term supplier relationships. But for strategic commercial deployments with 30-year lifecycles and complex financing structures, they’re increasingly the wrong choice.

HJT technology, double glass construction, and supplier partners with global reach and technology leadership—that’s where the market is heading. The only question is whether you’re going to be early to this transition or scrambling to catch up later.

The Unresolved Questions

I’d be dishonest if I didn’t acknowledge that massive uncertainties remain.

Will the US actually implement the aggressive tariffs being discussed, or will cooler heads prevail? How quickly will domestic manufacturing capacity scale up? Will the FEOC rules be modified to allow more flexibility? How fast will perovskite tandems move from laboratory to commercial production?

Nobody knows. Anyone who claims they do is selling something.

What we do know is this: the solar industry is in the middle of a fundamental restructuring. The simple, globalized supply chain that drove costs down for a decade is fragmenting. Technology is advancing faster than market infrastructure can absorb. Policy is being written in real-time, often contradicting itself.

For commercial buyers, distributors, and project developers, this environment demands a different approach. You need to be more strategic, more diversified, and more informed than you’ve ever had to be before.

The companies that treat procurement as a commodity-buying exercise will get burned. The companies that treat it as strategic risk management and value optimization will find opportunities others miss.

That’s the reality of solar in 2025. It’s not simple. It’s not stable. But for those who know how to navigate it, it’s full of possibility.

The question is whether you’re ready for what comes next.