Introduction: When Cooling Determines Solar Success

In solar energy systems, power generation may begin with panels, but true performance is decided by the inverter. Microinverters — the small, module-level converters that turn DC electricity into grid-ready AC — are now vital for maximizing output and reliability. Yet, their biggest challenge isn't conversion efficiency or power rating; it's heat.

Excessive temperature quietly shortens the lifespan of solar inverters, especially in high-irradiance regions. Without efficient heat dissipation design, even the most advanced сонячні фотоелектричні системи experience derating, efficiency loss, and premature failure. This article explores how microinverter thermal management has become a hidden yet decisive factor in ensuring the long-term reliability and ROI of modern solar power installations.

Why Heat Management Defines Microinverter Lifespan

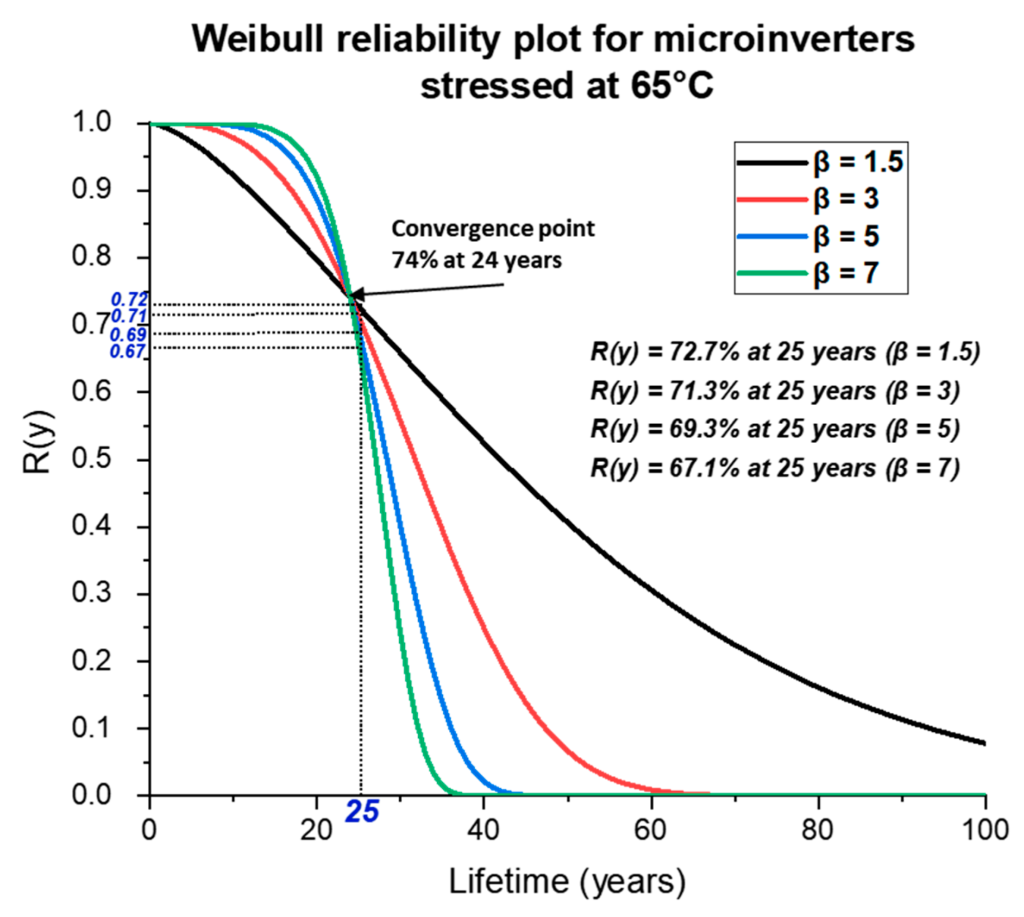

In continuous operation, microinverters face constant electrical and thermal stress. Every conversion cycle generates heat in semiconductor components such as MOSFETs, IGBTs, and transformers. When temperatures rise above 85°C, the failure rate of these parts can double for every additional 10°C increase — a principle well-documented in reliability engineering.

Figure 1: Reliability of microinverters under high-temperature stress — component failure rates rise exponentially beyond 85°C.

Studies by the National Renewable Energy Laboratory (NREL) confirm that temperature is one of the top three causes of inverter failure in field systems. Overheated microinverters can lose up to 5–10% energy yield annually due to thermal derating. In hotter climates like Southeast Asia or the Middle East, poor cooling design can reduce system performance even faster.

To maintain system uptime and investor confidence, heat must be treated as an engineering priority, not an afterthought.

Where the Heat Comes From

Understanding microinverter heat sources helps explain why cooling innovation is critical for modern solar projects.

- Power Conversion Losses: Every watt of DC converted to AC produces minor electrical losses, turning into heat inside power semiconductors and magnetic components.

- Switching Circuits: High-frequency switching improves efficiency but intensifies localized hot spots.

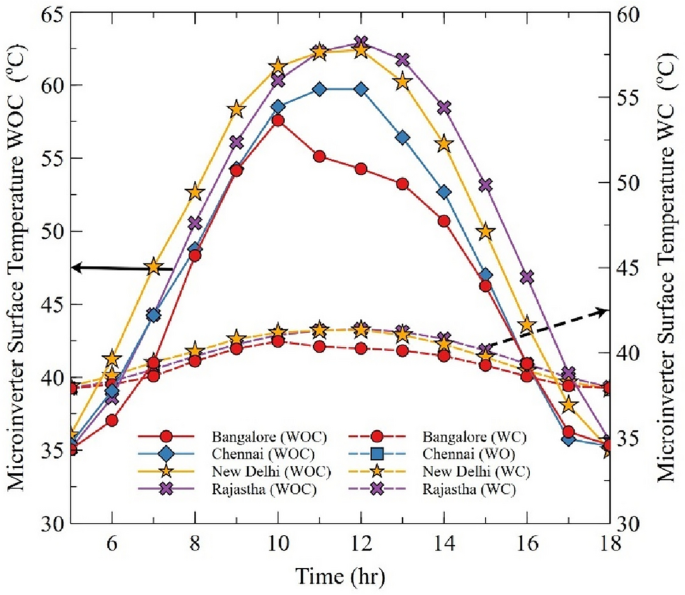

- Environmental Exposure: Mounted directly beneath PV modules, microinverters endure both radiant solar heat and limited airflow.

- Cumulative Array Effects: Multiple inverters clustered on hot rooftops amplify surrounding ambient temperature.

Data Table: Typical Thermal Loads in Microinverter Systems

| Heat Source | Average Contribution (%) | Key Mitigation Approach |

| Power Electronics Losses | 40–50% | High-efficiency components |

| Switching Circuits | 25–30% | Optimized PWM frequency |

| Sunlight Exposure | 15–20% | Reflective housing, shading |

| Ambient Airflow | 10–15% | Thermal layout & spacing |

Unlike string inverters that are usually installed in ventilated areas, microinverters work in the hottest part of the solar installation — directly under modules — making thermal management far more challenging.

Figure 2: Typical daily temperature profile of a microinverter mounted beneath a PV module in full sunlight.

The Engineering Science of Heat Dissipation

The next generation of high-efficiency microinverters relies on smart thermal design to stay cool. Let's explore how engineers are turning heat from an enemy into a controllable factor.

1. Advanced Heat Sinks and Fins

Modern microinverters use extruded aluminum or copper heat sinks that expand surface area for better convection. Some adopt fin arrays with microchannels that optimize airflow patterns. Computational fluid dynamics (CFD) helps predict airflow efficiency under different mounting orientations.

2. Thermal Interface Materials (TIMs)

Between chips and heat sinks, TIMs ensure low thermal resistance. Manufacturers now prefer phase-change materials or silicone-based pads that conform to micro-surfaces, improving conductivity by up to 30%.

3. Natural vs. Forced Convection

Most microinverters rely on passive cooling to avoid fan failures. However, emerging hybrid designs integrate miniaturized fans triggered only under extreme heat conditions — balancing silence with efficiency.

4. Enclosure Optimization

Compact housings are being redesigned with ventilation paths and heat-diffusing surfaces. Some microinverter enclosures now use graphite coatings to radiate heat more effectively.

Together, these innovations maintain component temperatures below the critical 70–80°C range — a threshold that separates years of stable output from early degradation.

Figure 3: Power output derating curve of a modern microinverter — showing how cooling preserves efficiency at high ambient temperatures.

Real-World Impacts: Efficiency and Long-Term ROI

Effective thermal management doesn't just protect components; it transforms the economics of solar systems.

- Higher Conversion Efficiency: Cooler inverters sustain peak efficiency for longer, preventing thermal derating losses.

- Подовжений термін служби: A 10°C drop in average operating temperature can extend inverter service life by up to 50%.

- Improved ROI: More consistent power generation means shorter payback periods for system owners.

- Lower O&M Costs: Fewer thermal-related failures reduce maintenance calls and replacements.

According to NREL field reports, thermally optimized microinverters demonstrate over 98% uptime across varied climates. For commercial and utility-scale installations, that reliability translates directly into stronger energy yield forecasts and investor confidence.

Figure 4: Comparative performance of microinverters with standard vs optimized cooling — improved energy yield and ROI over 10 years.

Trends Driving the Next Generation of Solar Inverters

As solar companies race toward higher efficiency and longer warranties, the inverter market is evolving with new materials and intelligent monitoring.

1. Graphene-Based Cooling Films

Lightweight graphene coatings offer superior thermal conductivity and corrosion resistance, especially useful for coastal or desert solar projects.

2. AI-Powered Thermal Management

Smart microinverters now integrate temperature sensors linked to machine learning algorithms that predict overheating risks and adjust power flow accordingly — an approach pioneered in large-scale PV farms.

3. Modular Thermal Designs

Future systems will feature swappable cooling modules, allowing easier servicing and extended product lifecycles.

The next wave of inverter development will combine smart diagnostics, heat mapping, and modularity — turning passive cooling into active system intelligence.

Sunpal's Perspective: Building for Endurance

At Sunpal, we believe that system longevity defines true solar value. That's why every Sunpal solar solution is designed with temperature resilience in mind — from inverter integration to thermal system layout. Our engineering teams evaluate each project using advanced thermal simulation tools to ensure stable operation in the most demanding climates.

Whether powering residential rooftops, commercial buildings, or off-grid solar installations, Sunpal's systems are optimized for long-term performance, safety, and return on investment.

In the world of renewable energy, reliability isn't luck — it's engineered.

Conclusion: Cool Inverters, Hot Performance

Microinverters may be small, but their impact on solar system reliability is enormous. As power electronics continue to advance, thermal management stands out as the hidden key to unlocking the next decade of solar efficiency. With advanced cooling materials, intelligent monitoring, and precision engineering, tomorrow's solar systems will not only produce more power — they'll do it longer, safer, and smarter.